In the case of non-magnetic materials, the colour penetration test (according to EN ISO 3059) is used as a display amplifier for crack detection. Typical fields of application are highly stressed turbine, engine or brake components and other safety-relevant components such as the wheel suspension and the chassis. These test procedures are summarized under the standard (ASTM E 1417/ ISO 3452-2).

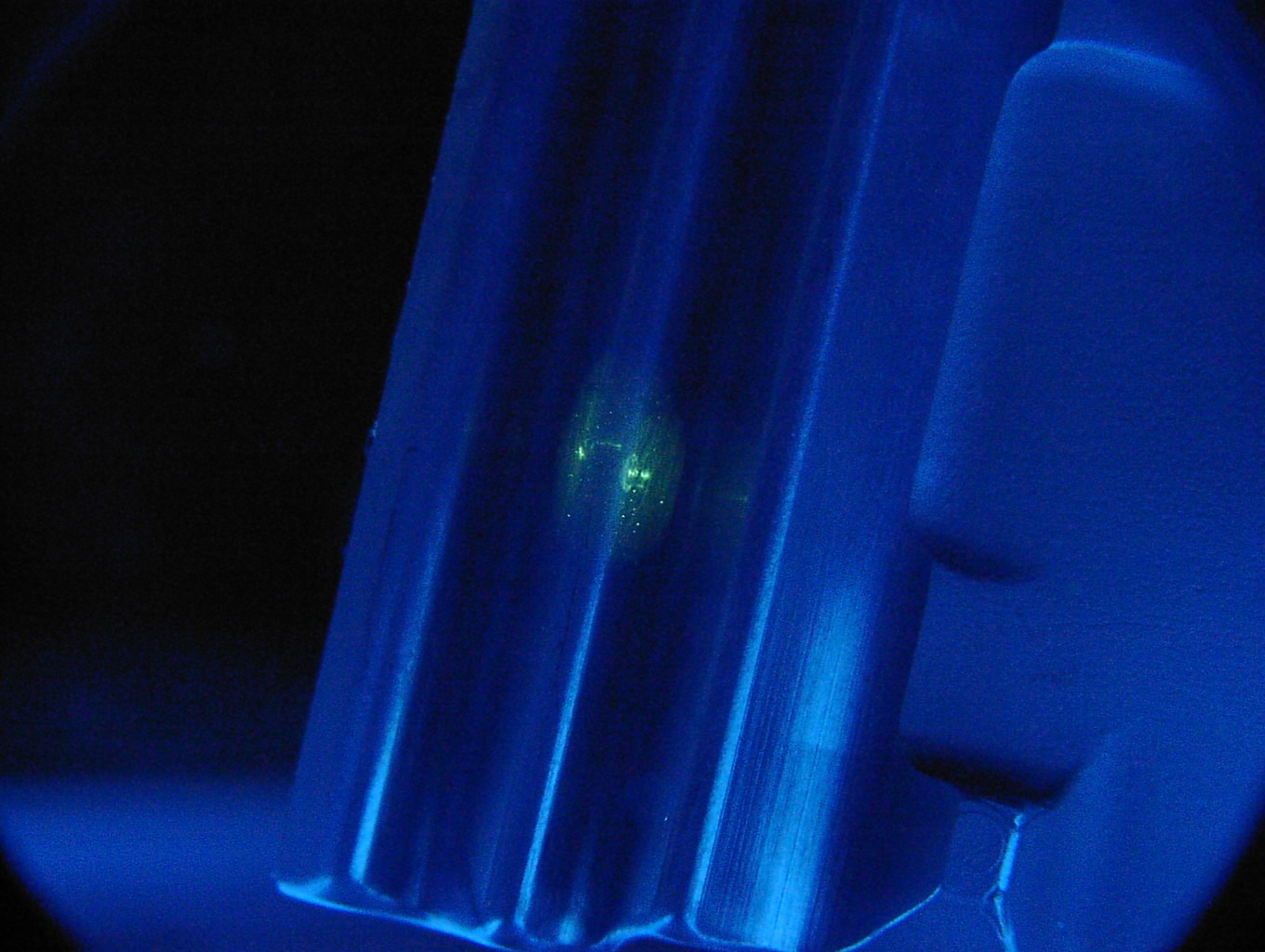

Pores at the foot of an engine turbine blade, captured with UV LED flash

Automatic inspection software

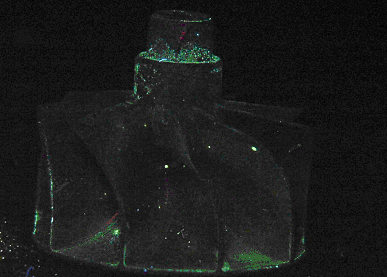

Isolated pores on a turbocharger

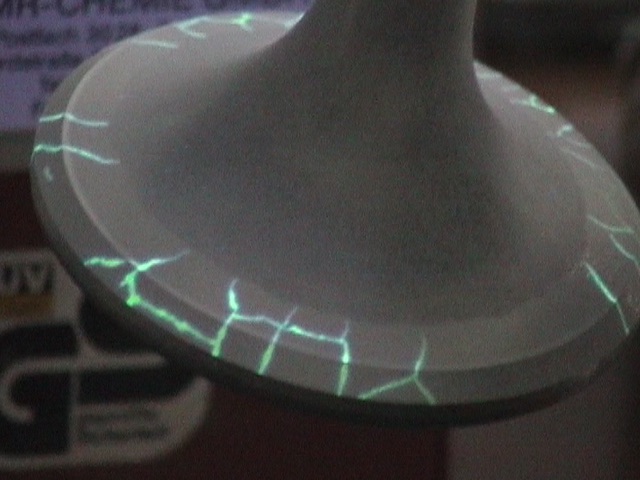

Cracks in a valve disc